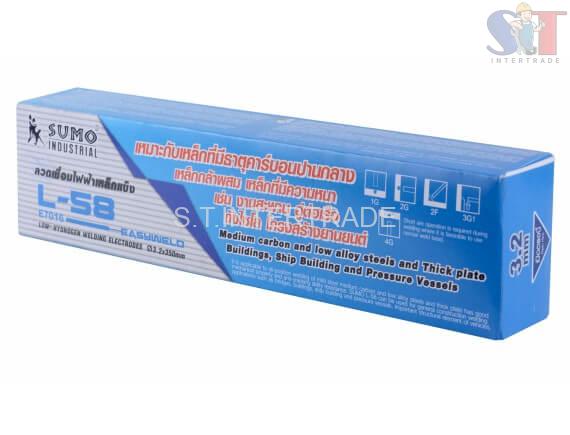

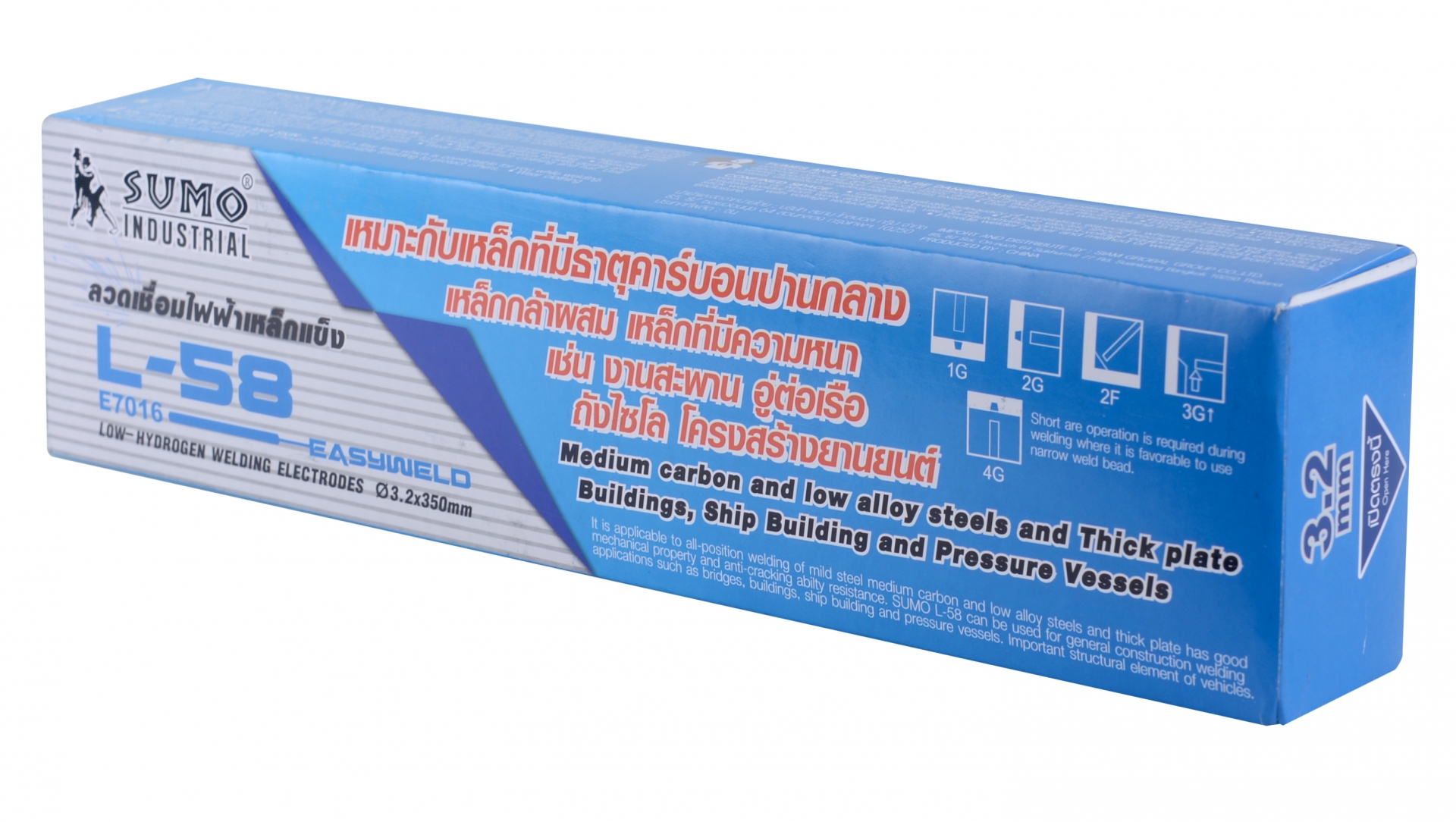

ลวดเชื่อมไฟฟ้าเหล็กแข็ง SUMO E7016 3.2mm (20kgs./ลัง)

1,250.00 บาท

ลวดเชื่อมไฟฟ้าเหล็กแข็ง L-58(E7016) Ø3.2mm เหมาะกับเหล็กที่มีธาตุคาร์บอนปานกลาง เหล็กกล้าผสม เหล็กที่มีความหนา เช่น งานสะพาน, อู่ต่อเรือ, ถังไซโล, โครงสร้างยานยนต์

- เหมาะกับเหล็กที่มีธาตุคาร์บอนปานกลาง เหล็กกล้าผสม

- ขนาด (size) : Ø3.2x350 mm

- Current : 90-130A

- น้ำหนัก (Weight) : 5 kgs/box, 20 kgs/Ctn

*สนใจสอบถามเพิ่มเติม 082-078-5222

E-Mail : s.t.inter@hotmail.com

Line : @stinter

*สนใจสอบถามเพิ่มเติม 082-078-5222

E-Mail : s.t.inter@hotmail.com

Line : @stinter

สนใจสอบถามเพิ่มเติม

รายละเอียดเพิ่มเติม

ลวดเชื่อมไฟฟ้าเหล็กแข็ง SUMO E7016 3.2mm (20kgs./ลัง)

LOW HYDROGEN ELECTRODE SUMO E7016 3.2mm (20kgs./CTN)

It is applicable to all-position welding of mild steel medium carbon and low alloy steels and thick plate has good mechanical property and anti-cracking ability resistance SUMO L-58 can be used for general construction welding application such as bridges, buildings, ship building and pressure vessels. important structural element of vehicles.

Specification

| Trademark | E7016 |

| ขนาด (size) | Ø3.2×350 mm |

| Current | 90-130A |

| น้ำหนัก (Weight) | 5 kg (box) 20 kg (Ctn) |

| บรรจุ (Pack) | 4 Boxes/Ctn |

Guidelines for use

- All water, rust and oil should be complexly removed from base material to prevent cracking and blowholes.

- For improved impact properties, avoid used of excessive amperage levels.

- Backstep method should be applied to prevent blowholes and pits during arc start.

- Arc length should be kept as short as possible during welding

- If weaving is required, the width should not exceed 3x the diameter of the electrode.

Redrying

- All controlled hydrogen electrodes will perform optimally when they are dry.

- Excellent protection against moisture pick-up in good storage conditions.

- Should redrying be necessary, remove electrodes from the packet/ container and spread thinly and evenly on racks in a ventilated oven

- For electrodes that have had a short or mild exposure to the atmosphere then re-drying at 572 F°(300 °C) for 1 hour will be sufficient

- For electrodes that have been exposed to longer or more aggressive conditions or for critical work re-drying at 572-662 °F(300-350 °C) for 1-2 hours is recommended. After re-drying electrodes should be stored in a hot box